Looking for a safe and productive solution for your next construction project? Check out our Mast Climber Monday blog post, featuring a project we worked on with Trinity Masonry a few years ago. Using Hydro Mobile M2 Mast Climbers with a M2 Hoist, our team helped keep the First National Bank project in Killeen, Texas running smoothly and efficiently. With a hoist capacity of 4,000 pounds and spacious 7' front-to-back mast climber decks, these reliable and efficient machines provided a safe and productive work environment. Don't miss the photos from the construction process! Contact us at Spec Rents to learn how we can help you increase productivity and safety on your next project, no matter the size or complexity.

Read moreBoost Your Construction Project's Efficiency with the Hydro Mobile M2 Hoist

Maximize your construction project's efficiency with the Hydro Mobile M2 hoist. Capable of hoisting up to 4,000 lbs, the M2 hoist can help you overcome common challenges like limited access, inefficient loading, and waiting on crane time. Learn how the M2 hoist can help you stay on schedule and avoid costly delays.

Read moreM is for Masonry: Hydro Mobile's M2 Mast Climber

M is for Masonry

Hydro Mobile’s M2 Mast Climber

When you start looking at scaffolding on masonry projects up North everyone uses mast climbers. In fact, I had a customer call me the other day when he was in Iowa to tell me that he saw someone using Hydro Mobile M2 mast climbers on a dumpster. I laughed and said, “I told you they weren’t just for high rises and long, straight walls.”

You see, down here in Texas, the tide has been slower to turn to using mast climbers. With lower labor costs than in the northern states, Texas contractors haven’t had to look to innovation as much to help with cutting costs and lowering productivity over the years. Times are changing and mason contractors in Texas are starting to see that it’s cheaper to spend more on innovative equipment and scaffold that takes fewer employees and less time, while improving productivity and safety. In the past year I’ve had multiple contractors that started using Hydro Mobile for the first time tell me that they wonder why they’d waited so long to go this direction.

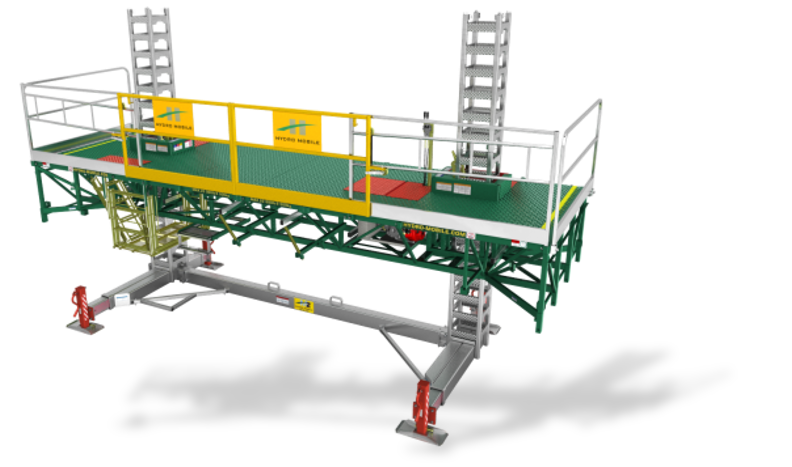

Here’s what sets the M2 Mast Climbers apart and why they work so well for Masons:

22,000 lb capacity. That’s a lot. But remember that masonry is heavy work. A pallet of block may weigh between 2,000 and 3,000 lbs.

What does having 22,000 lb capacity mean for mason contractors? You’ll be able to adequately stock your materials, your mortar, your saw, your crew, tools, and even probably have capacity left over for a port-a-potty.

7’ wide deck. This is from front to back (before adding walk-boards).

What does this mean for companies? Not only do you have the capacity (see above note) you need, but you’ll have room to put all your materials and equipment with room left over for your laborers to move around productively.

Hoist system. Why go to the expense of renting a crane or larger forklift when the M2 Hoist system can do the job for you? Its 4,000 lb capacity handles full pallets of brick and block easily and it’s hydraulic power pack delivers 65’ per minute lift speed.

What does this mean for mason contractors? No more waiting around for materials. No more stocking from the building, which takes a lot of labor. Less expense for renting cranes and larger forklifts.

Hydro Mobile M2 Mast Climber with Hoist and Multi-Purpose Inserts at Texas A&M University in College Station

Solid deck. How many boards do you use with conventional frames? A lot. And boards aren’t cheap. And they’re not light weight either. Most General Contractors are requiring every level to be decked out completely, requiring a lot of boards.

What does a solid deck mean for your crew? Besides not having to use money and time for walk-boards, you also have a solid deck with fewer trip hazards and an easier way to push things around on wheels such as mud tubs or brick/block carts to cut down on labor time. (If you’ve not tried using a Hog Cart or the Hog Troughs, give them a try).

Monorail System. Anyone that has ever done a large stone job knows how hard keeping up with production and safety is for masons and laborers alike. Using a monorail system allows crews to slide loads along instead of manually handling them.

What does this mean for your team? Less lifting injuries. Better productivity. Some masons use monorails systems with their conventional frames. Although, this is still an improvement over man-handling large materials, it requires re-positioning the system as you go up/down the wall. With Hydro Mobile the monorail system goes with you.

Increased Productivity. Because the platform goes up with the wall, materials and working height can always be placed at a comfortable height for your crews.

What does this mean for mason contractors? It requires less bending and lifting for your masons, resulting in happier, more productive team members. Plus, there’s no question this is better from a safety perspective. But wait, there’s more. No more stopping to raise the walk-boards. Imagine getting that time back!

Make Returns and Reach In-sets and Step-backs. Hydro Mobile M2s are built to accommodate up to 8 walk-boards for your crews to use in addition to the 7’ platform. Using the Multi-purpose Inserts, you can reach 14’ beyond the 7’ platform.

What does this mean for your project? In many cases, it gives you the ability to make returns without having to set up another set of scaffold. It often helps with those projects that have in-sets or step-backs so you can reach the work surface without having to set another scaffold system up. I’m often told that Hydro Mobile M2s are made for long, straight walls, not cut up projects. While it’s true that they do work well on those types of walls, the ability to use 8 walk-boards or the Multi-purpose Insert makes Hydro Mobile M2s a good choice for cut up projects too because of the flexibility and reach they provide.

Hydro Mobile M2 Mast Climber - Masons laying on interior with multiple returns.

Hydro Mobile M2 Mast Climber - Masons using extended outriggers and walk-boards to reach wall with bump-out.

Quick Set-up. Think about how long and how many of your crew it takes to set up 148’ linear x 35’ vertically. Is it longer than a day? Probably. You can install this amount of Hydro Mobile M2 mast climbers in 3 - 4 hours with an experienced crew of 2 scaffold builders and an operator.

What does this mean for mason contractors? Faster setup = reduced labor costs and getting on the wall faster.

Safety. Safety systems are built into M2 mast climbers, including built in guardrails with integrated toeboards and material gates for convenient loading.

What does this mean for companies? Built-in safety systems mean less chances of human error that can lead to serious injuries such as missing guardrails, etc. Additional safety comes in the form of proper ergonomics for masons not having to bend and lift as much.

Hydro Mobile M2 Mast Climber includes built-in safety features such as guardrails, toeboards, anchor points, and materials gates for convenient loading.

It’s obvious that the Hydro Mobile M2 mast climbers are made for Masonry, hence the “M” in M2. Although they’re designed to meet the challenges of the masonry industry, they are a great shared system for multiple trades also because of the above safety and productivity topics seen above. Check out our project page for some pictures of these in action. Let us know if you’re curious if mast climbers might solve some of the safety and productivity issues your company is having. We are always happy to help a contractor find the best solution for their specific challenges.

Spec Rents is the proud distributor of Hydro Mobile for Texas. Although we are technically an equipment company, we’re not just in business to sell equipment. We provide our customers with safety and productivity. Let us know if we can help you achieve your company’s goals.

Post by: Elizabeth "Liz" Graves, Sales Manager at Spec Rents, LLC. Contact Liz at lizg@specrents.com

Hydro Mobile M2 Mast Climbers - Dallas, Texas